Lorem ipsum dolor sit amet, consectetur adipiscing elit, sed do eiusmod Lorem ipsum dolor sit amet consectetur adipiscing elit, sed do eiusmod lorem ipsum

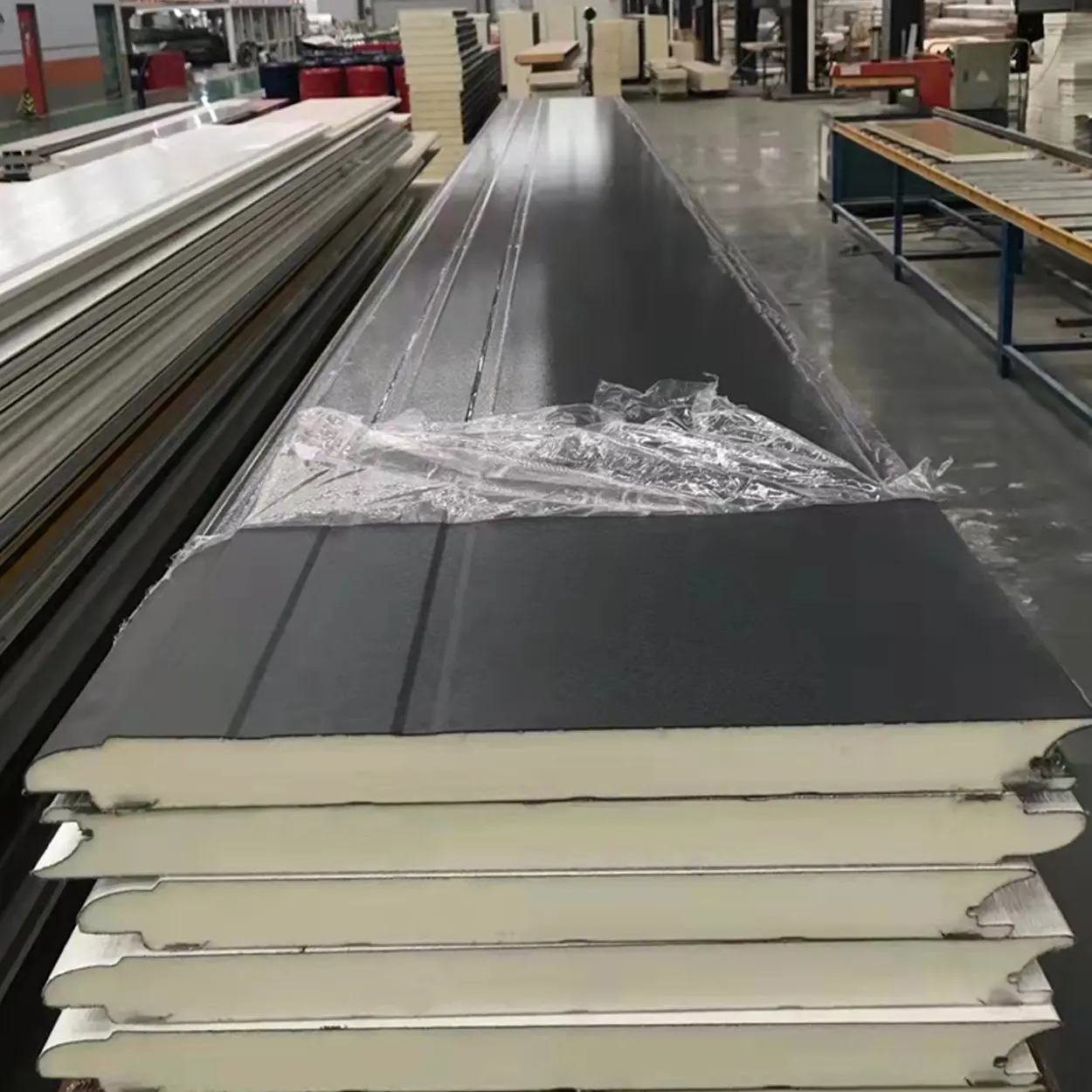

15 Benefits of Insulated Panels for Aluminum Doors

Insulated panels for aluminum doors are a game-changer for both residential and commercial properties.

How to Install Aluminum Door Sealant?

Proper installation of aluminum door sealant can significantly improve the energy efficiency and weatherproofing of your home.

15 Tips of Aluminum Door Frame Anchored to Masonry Wall Installation

Installing aluminum door frames securely into masonry walls is a critical part of construction that ensures long-lasting durability and aesthetic appeal.